From the Loom to the Cloud — Textiles Get Smart

Linen inventory distortion from out-of-stocks and overstocks costs the hospitality industry around the world hundreds of millions of dollars every year.

The lack of linen inventory visibility results in:

- Inaccuracy in linen assortment planning and allocation

- Increase in linen purchases and associated linen management costs

- Decrease in housekeeping service quality

- Loss of room sales

- Decline in customer satisfaction

At the same time, laundry and linen inventory management as well as other related operations are undergoing a significant digital transformation, due to the power of RFID technology and cloud-based software solutions.

Track and trace operations can be orchestrated in a concerted workflow for truckloads of specialized textiles powered by RFID technologies that manage everything from hotel bedsheets to towels, staff uniforms, nursing home residents’ clothing and a whole lot more.

How does it work?

Consider hundreds of soiled linen pieces from the laundry bins of a five-star hotel that need to be cleaned, sorted and properly returned to the linen rooms on each floor in time to ensure availability for housekeeping.

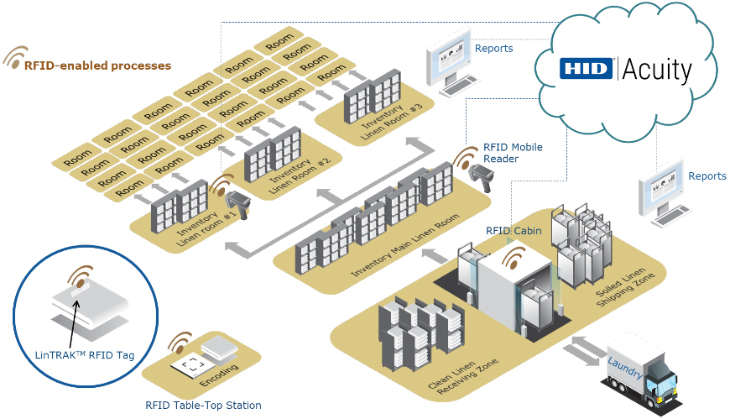

To facilitate management, each linen item is embedded with an RFID tag, such as HID’s LinTRAK tag. LinTRAK looks like a care label but contains a unique identifier which gets scanned at each step of the laundry cycle to generate a wealth of valuable data for the housekeeper and the commercial laundry. The tracking capability of this tiny device offers textile services professionals the ability to not only track the linen as it moves through the laundry cycle — ensuring it gets returned to linen shelves in a timely manner, but also track the number of washes in order to evaluate the linen quality. This data is managed by cloud-based software such as HID Acuity, which helps ensure that the laundry item is properly returned to a satisfied customer.

With over dozens of installations at some of the world’s finest hotels, HID understands the value that this RFID solution brings.

Weaving in the Laundry RFID Solution From the Beginning

The key to linen management is possessing knowledge about your linen lifecycle and location. But the real challenge — or innovation, depending on how you look at it — starts at the beginning, when the linen is first woven and the RFID tags are directly embedded into the fabric at the same time.

There are multiple ways of securely and discreetly integrating RFID tags into textiles. The tag (or transponder) can be sewn into a hem or inside a small fabric label (e.g., a brand label). Some RFID tags come with a specific heat-activated adhesive coating on one side so that they can be heat-sealed directly onto the textile, ostensibly turning it into a smart textile.

Carefully following integration instructions and recommendations guarantees the tag performance throughout the life of the textile product, regardless of repeated washings, exposure to cleaning chemicals, sterilizing heat and water press extractors.

As RFID-enabled linen becomes the norm with fine hotels and other facilities, potential customers may be wary of the entry costs of such a solution. A more cost-effective alternative is to integrate the tags during the textile production process (known as source tagging) via a dedicated piece of equipment such as HID’s IFF-1. Compared to the cost of manual attachment (also called retrofitting), which can be up to 30 cents per item, source tagging has virtually no cost, since linen is automatically RFID-enabled in a continuous flow with no disruption in the linen manufacturing process.

At the forefront of RFID innovation, HID works with some of the world’s largest linen manufacturers, focusing on hospitality and healthcare linen, to design solutions that integrate RFID tags directly and automatically into linen items virtually at the loom level with a patented labeling machine and UHF RFID tags on rolls.

Embedding tags into textile products from the beginning literally facilitates the entire lifecycle process — from the loom to the cloud.

As a stakeholder, you may not have the resources to do that yourself, but rest assured there are textile manufacturers who have already adopted that production process and are ready to work with you to achieve real value-based efficiencies in your housekeeping/laundry/linen operations.

The integration of RFID tags into high-volume linen during the manufacturing process using an integrated system like HID’s Integrated Fast Feeder (IFF-1), saves both labor and costs, which then leads to significant benefits to our customers further down the value chain.” – Fabrice Morini, Sales VP at HID Textile Services

Whether customers are enterprise hotels or guests themselves, when you invest in a linen inventory management platform for smart textiles, users will immediately see the benefits of this digital transformation.

Leveraging the Power of SaaS-Based Linen Inventory Management

Cloud-based management software, sometimes referred to as SaaS, or software as a service, has a vital role to play in the entire textile services ecosystem.

SaaS-based linen-management platforms such as HID Acuity combine industry leading RFID technology (tags and stations) with cloud software and integration services to enable laundry professionals to accurately track linens, uniforms and other textile assets. This improves inventory visibility, reduces shortages and automates processes.

Here is a glimpse of how it works:

Linen data are collected, stored, analyzed and acted on, in real time, from the RFID equipment. Acuity enables the transformation of the RFID data into rich, interactive, cloud-based dashboards and reports. The reports provide a comprehensive and real-time overview of linen stocks by article reference or individual items, per zones in your facility and at your laundry suppliers’ sites.

Seamlessly integrated into laundry processes, Acuity allows institutions to efficiently identify, track and manage linens, uniforms, workwear and more, while increasing financial gains through reduced operational costs, optimized stock movements and purchases, and improved customer satisfaction.

This rich fabric of tightly integrated hardware and software solutions (from the loom to the cloud) is scalable, cloud-based and proven to offer a huge ROI to any operation, from hotels to casinos, theme parks, nursing homes and more. It is a robust system that leverages the power of smart textiles and SaaS combined with smart stakeholders who see the value in RFID technological innovation to optimize their textile-based operations.

For a deeper dive into how RFID technology powers linen inventory management, read our white paper, Optimizing the Linen Management Process for Industrial Laundries or contact us.

Nick Iandolo is an experienced Senior Marketing Strategist specializing in Content Marketing and Corporate Communications Writing, primarily for market-disrupting technology organizations. He has a knack for taking highly technical materials from subject matter experts and translating them into actionable marketing collateral for both digital and print. His most recent roles were senior content creator positions for Exponent and PTC, where his work has been featured in publications such as Morning Consult, NewDesign Magazine UK, SmartCard Identity News, and Construction Outlook. In his personal life, he is a creative writer penning digital tech trends blogs and science fiction stories, and he is also an enthusiast Spartan Race athlete. Nick lives just outside of Boston Mass with his wife, daughter, and Golden Retriever.