RFID for OEMs: Top 3 Reasons to Embed RFID Tags

OEMs are increasingly turning to embedded RFID to not only enhance their own asset management processes but also add value to their products. Here’s why.

When it comes to leveraging RFID, OEMs have a unique opportunity: They can actually design a product with an embedded tag, providing better performance, lower cost and higher tag durability. This can’t be done after original manufacturing, or risk violating engineering specifications. All asset owners after the OEM will have to find another way to attach their RFID tags should they choose to deploy an RFID system.

So, OEMs have an important decision to make: Should they embed RFID tags in their products? More often than not, the answer is yes. Here are three reasons why.

#1. Product Validation

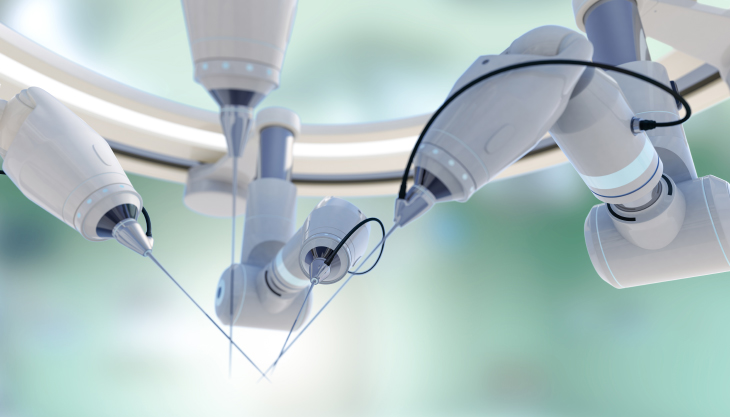

OEMs can validate different types of products with RFID, like devices attached to parent devices (surgical robots and tools) and consumables (analytical devices and reagents). RFID can help with IP protection, warranty management and calibration.

IP Protection & Warranty Management

Some end-users may attempt to use a child device that is not made by the same manufacturer as the parent device. When this happens, the parent device will not be able to communicate with this third-party, differently programmed piece of equipment. Unfortunately, some may claim fault on the part of the OEM for ineffective equipment. This is where RFID comes in to protect the OEM.

An RFID tag embedded in a child device and a reader installed in the parent device will be able to validate that the right device is being used. If a third-party device is detected instead, the OEM is notified and the warranty voided. This protects the device physically from possible damage as well as releases the OEM from liability if the equipment fails due to the use of the third-party device.

Calibration

The RFID system can also ensure that the devices have been calibrated properly so the parent and child devices interact appropriately. In manufacturing, products aren’t exact copies of each other — there is a statistical variation even between “identical” devices. Internal mechanisms will move differently inside of each device, which means the host device needs a way to know the variation before it moves. With RFID, the host device knows how to correct for these variations in order to operate with optimal capacity because the host scans the tag and is directed to a database where the calibration information is stored.

Take a surgical robot as a parent-child device example. The child devices that can be used with the robot all need to be related to this host device. Pieces like scalpels, staplers and cauterizing devices could all be needed during a given surgery, and each time a new piece is attached to the host device, the host needs to know and be able to work with it. If not, there could be delayed surgeries at best and catastrophic results at worst. In the case of any intuitive surgical tool, multiple gears and pulleys need to work in order to move in the way a surgeon wants it to move. For example, a certain pressure needs to be calibrated so that veins aren’t crushed and skin tissue isn’t injured. To avoid an issue like this, OEMs can validate and calibrate all the devices being used with the host device with an embedded RFID system.

For consumables, an example would be a printer and ink cartridge. If you put an RFID reader in the printer and embed an RFID tag in the ink cartridge, the printer will be able to detect and validate the ink. Another company’s ink might clog this company’s printer, so the RFID system in place can protect the printer from damage if a third-party ink is detected.

#2. Lifecycle Management

RFID can also help OEMs collect data for the entire lifecycle of the product.

A product’s lifecycle begins at the factory. Embedded RFID at the very beginning of the product’s life will ensure you capture the most accurate information about the state of an asset. This is important for equipment under warranty or equipment that needs engineering updates or periodic maintenance. OEMs can even use RFID while the asset is still in their factory as a work-in-process tracking device.

When it comes to lifecycle management, medical devices are a great example. Regulations require medical devices to have a unique identification (UID) so they can be tracked throughout the lifecycle. It’s important to have unique data about each medical device for warranty, recall and maintenance purposes. But these UIDs are limited in that they are just that — an ID. RFID allows OEMs to leverage these UIDs in a more efficient manner. If there is ever a recall on a medical device, OEMs will be able to quickly identify those devices using the embedded RFID system — instead of tediously reading serial numbers on a list.

Likewise, products with embedded RFID tags can be tracked throughout the rest of the supply chain from shipping to distribution to even retail. OEMs will have visibility into the product’s path as not only a lifecycle management tool but also an inventory management tool.

#3. Competitive Advantage for Customers

The benefits of embedding RFID tags don’t stop at OEMs — OEM customers will certainly be able to take advantage of RFID functionality as well. Even if the OEM itself doesn’t leverage the RFID tag, the customers may want to.

This gives OEMs an edge in sales and marketing. When you engineer a product with embedded RFID, you’re able to give your customer helpful functionality at a very attractive price. This is because looking for the right tag and attaching it to an asset down the road is a longer and more complex process. It’s almost always preferred to engineer a tag’s placement from the start.

Products with embedded RFID tags are ready to incorporate into a system immediately, so they are a huge marketing asset for OEMs. Not to mention, customers will appreciate working with an OEM that takes the time to streamline the asset management process for them.

Conclusion

To embed RFID tags for OEMs, RFID tags can be molded into a plastic, rubber or composite element and placed inside a product so as not to be obvious to the end-user or at risk of obstruction from external forces. However, no matter where an RFID tag is placed inside a product, an RFID tag reader will still be able to see it, which is why RFID tags are superior to barcodes in many applications.

OEMs can drastically improve their business processes (and boost their sales and marketing) by embedding RFID tags into their products from the very beginning. — Ken Horton, former CEO, Vizinex RFID

To learn more about manufacturing medical devices with embedded RFID tags, watch HID Global/Vizinex RFID’s webinar replay, Medical Device Manufacturing and RFID.

Ken Horton is the former co-founder and CEO of Vizinex RFID (now an HID Global Company). Ken has worked in the RFID field since 2008 in operations, engineering, sales and marketing roles. Prior to the founding of Vizinex, Ken served in leadership positions at several technology firms. He now serves as a consultant for HID Global's Identification Technologies business segment.