Four OEM Benefits for RFID-Enabled Medical Devices

RFID technology has changed the ways in which original equipment manufacturers (OEMs) fabricate, distribute and market modern medical devices. In turn, medical facilities and their patients reap the benefits of this technology in ways that are real and measurable, by increasing revenue and reducing costs and human error, to name a few.

The following four examples scratch the surface of the advantages most healthcare-related OEMs can enjoy from adopting RFID technology into their medical device products.

Medical Device Asset Tracking for Product LCM and Proper Billing

Without RFID tags and readers, the task of tracking medical devices such as surgical instruments becomes increasingly more difficult and labor-intensive. However, with the value-added benefit of asset tracking for an OEM’s product line, embedded RFID offers a competitive selling point to healthcare organizations.

Asset tracking is among the fundamental benefits of RFID-enabled medical devices. Having real-time information about the location and status of a vital piece of equipment can lower costs compared to other outdated methods. For example, some asset-tracking benefits for OEMs and their customers can include:

- Monitoring the entire lifecycle management (LCM) of a medical device up to the point where it needs to be retired and proactively replaced as appropriate

- Ensuring proper billing by knowing exactly what instruments were used and when

- Tracking the device from manufacturing, distribution and supply chain, to customer/sales rep inventory management

Medical Device Authentication

Knockoff medical devices are a problem, but RFID offers a solution — one that can help differentiate an OEM from its competitors and that customers will appreciate. Benefits include:

- Ensuring that the correct surgical kit is used for a particular procedure, when the appropriate reader is properly set up in the OR by the healthcare facility — another potential add-on upsell

- Proving that an implantable object, such as a breast implant, complies with all FDA and other agency regulations — especially in the case of a product recall

- Preventing black and gray market counterfeiting of devices by ensuring their authenticity and top-notch quality — accomplished by disallowing either a competitor brand name or knockoff consumable medical device product to function with a base device

- Providing a permanent identification number that will never wear off and can be scanned/read even when inside a patient’s body

- Reading RFID data from multiple devices at the same time, unlike alternative approaches such as QR codes which cannot

With regards to complying with agency regulations, FDA compliance is a fundamental selling point. The FDA requires that all medical devices carry a UDI, or unique device identifier. Adding an RFID tag with a permanent 15-digit UID, or unique identifier, and marrying it to the FDA’s UDI allows for seamless traceability of a medical device, even when physical documentation like a certificate cannot be located. This multi-purpose benefit also applies to medical device asset tracking.

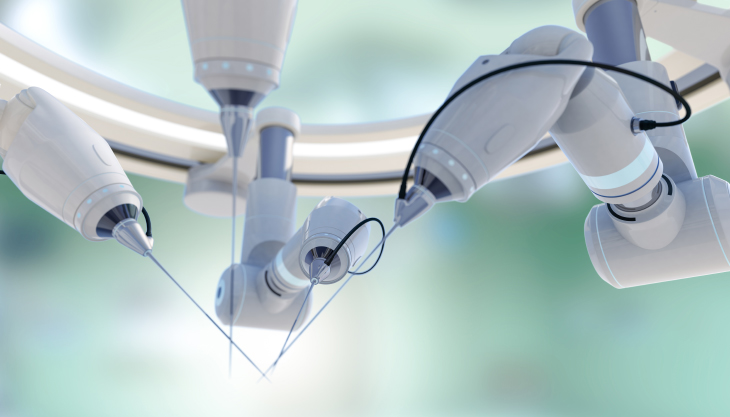

Autocalibration for Base-to-Consumable Medical Devices

Some surgical instruments, even robotic ones, require not only authentication but also autocalibration. In other words, when one device (such as a parent or base device) is connected to another (such as a child or consumable device) the two must be calibrated for proper use.

Autocalibration can include setting device parameters such as speed, torque, RPM and depth of penetration. For OEMs, this benefit can be featured as eliminating both human error and manual labor.

Autoclave Tolerance in RFID Tags

Autoclave-tolerant RFID tags is one of the newest and most exciting benefits of RFID-enabled medical devices. Their advantages for OEMs and their customers include:

- A small footprint, i.e., low profile, mount-on-metal tags

- Survivability to more than 1,000 autoclave cycles

- A low ergonomic impact

- Exemplary read range

- Multiple sizes / lengths

- Adaptability for overmolding / overspraying or embedding in metal

- Resistance to a wide range of chemicals

These HID tags are made with proprietary techniques that represent the cutting edge of RFID manufacturing processes. This is a potential competitive advantage over OEMs who cannot support the harsh demands of autoclaving.

HID Global has been in the RFID market since the early 1990s, with medical devices as a top priority. We have completed many projects with many leading medical device OEM companies and are working on more, as well as developing new ideas and new use cases from OEMs, which drive our innovation. HID offers several off-the-shelf and custom design options, and we are always looking for ways to further enhance our customers’ devices to help them eliminate human error and increase efficiency, safety and revenue. — Caryn Mills, Medical Device Sales Director, HID Global

For a deeper dive into the benefits of RFID-enabled medical devices for OEMs, check out HID Global’s webinar replay Medical Device Manufacturing and RFID.

Nick Iandolo is an experienced Senior Marketing Strategist specializing in Content Marketing and Corporate Communications Writing, primarily for market-disrupting technology organizations. His work has been featured in publications such as Morning Consult, NewDesign Magazine UK, SmartCard Identity News, and Construction Outlook. Nick is also a Spartan Race athlete, and lives just outside of Boston Mass with his wife, daughter, and Golden Retriever.