Top Five Industries That Benefit from Wireless Condition Monitoring

Wireless Condition Monitoring (WCM) has been a boon for many industries. Before the development of remote active sensors that can detect 3-axis vibrations, temperature and moisture conditions on equipment, sensors had to be hardwired and were cost-prohibitive to encompass an entire fleet of machines — like a factory floor. But now that is changing thanks to wireless networks that have proven effectiveness when it comes to monitoring hard to access equipment, over a broad area and often under harsh environmental conditions.

But the real benefit is cost-savings for a plethora of areas — from heavy industries to logistics to facilities management and more.

This blog post outlines the top five industries that benefit from wireless condition monitoring.

1. Heavy Industries — Energy Production

In 2021, the operating revenue associated with generation, transmission and distribution of electricity from the electric power sector in the United States alone was estimated at $494.65 billion dollars.

GE Hydro, a large industry leader in hydrodynamic power generation, operates massive rotating turbines at installations such as the 14-gigawatt Itaipu Hydropower Plant — the world’s second-largest facility of its kind — straddling the border between Brazil and Paraguay.

GE Hydro’s turbines and generators represent more than 25% of the total installed capacity worldwide.

Their renewable energy segment of the overall conglomerate for General Electric tops $16 billion dollars annually.

For the billions of people who depend on GE for their electricity needs, unplanned equipment failure could be a catastrophic loss of not only revenue, but lives.

One of GE’s subcontractors, Asygn, partnered with HID to develop a state-of-the-art wireless condition monitoring sensor solution targeting the high-capacity rotating turbines operating in the harsh environment of hydroelectric power generation. This solution integrated Asygn’s Integrated Chip (IC chip) (which captures temperature and strain measurements) with HID’s RFID antenna (capable of wirelessly transmitting the data to an RFID reader). The RFID reader works as an intelligent gateway capable of calibrating, collecting, filtering, averaging and transmitting data locally.

GE’s performance management platform software then uses machine learning to parse the data into actionable insights including predictive fault detection — helping to minimize downtime in a mission critical operation.

2. Heavy Industries — Materials & Resources Extraction

“Rising consumption fueled by a growing middle class has seen the amount of primary materials extracted from the Earth triple in the last four decades,” according to a recent report by the United Nations Environment Programme-hosted International Resource Panel (IRP).

According to the 2016 report, the global economy grew from $15.4 trillion in 1970 to $51.7 trillion in 2010 — not adjusted for inflation — and global material use reached 70.1 billion tons in 2010, up from 23.7 billion tons in 1970.

This is a staggering industry with more markets than can be listed here.

The salient point is that the equipment required to extract these materials and resources are all susceptible to breakdowns by virtue of the harsh environments in which they operate.

Case in point, an offshore oil rig in the North Sea could be drilling into the seabed hundreds of meters down — no place for equipment failure. However, with a 3-axis rotation and vibration sensor attached to the drilling equipment, chances are good that a breakdown can be quickly mitigated before it happens as in example #1.

Wireless condition monitoring (WCM) offers this heavy industry market the following benefits:

- Energy efficiency for upstream oil and gas facilities

- Reduced maintenance costs

- Materials degradation (corrosion) monitoring

- Improved field communications

- The ability to digitally map a plant (Digital Twin)

- Mining automation

- Improved safety conditions

- Longer machinery lifespans

- Pipeline management

- Greenhouse gas emissions control

- Location intelligence

Within this type of industrial ecosystem, the most important element of WCM is the provision of data that can be used for predictive maintenance and other Industry 4.0 applications such as digital twin — the latter offering a real-time look at what’s actually going on inside the equipment’s physical counterpart enabled by the affixed WCM sensors.

3. Transportation Services — Automotive & Aviation

From self-driving cars to passenger aircraft, the main tenet for any mode of transportation is safety.

Automotive

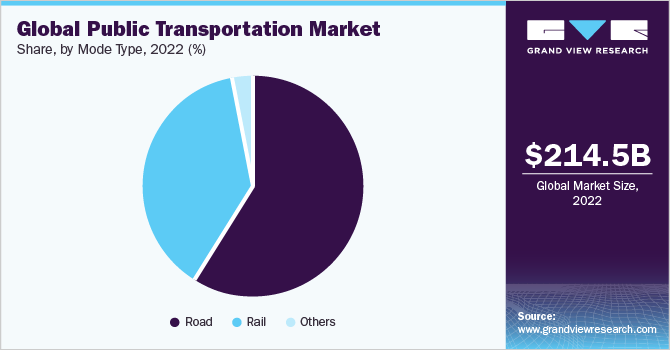

The global public transportation market size was valued at USD $206.7 billion in 2021, and is expected to expand at a compound annual growth rate (CAGR) of 5.9% from 2022 to 2028, according to a recent report from Grand View Research.

Any modes of public transportation require rotating equipment and power generating engines to be constantly monitored and maintained. Though larger vehicles, such as trains, are an obvious candidate for WCM, fleets of self-driving cars in the future will also require the same level of monitoring.

A study from Intel and Strategy Analytics estimates that driverless vehicles could represent UDS $7 trillion of economic activity annually by 2050.

Machine learning is one of the key tools behind this growing industry. Automated driving systems (ADS) are not only use algorithms to control system behavior, but also curate collections of training data for the algorithms to learn from throughout the entire product lifecycle and across the deployed fleets. Internet of Things (IoT) connected WCM sensors are integral to enabling that data collection and distribution — not just from car to cloud, but between ADS cars on the road working like a hive mind so as to not crash into one another.

Aviation

According to Statista.com, the market valuation of the global airline industry in 2021 was $471.82 billion dollars, down 41.5% from 2018.

With airlines looking to cut costs where they can, keeping equipment up and running —particularly aircraft engines — is paramount to both cost savings and passenger safety.

A recent article published by Exponent titled When Aircraft Engines Fail Successfully, cites that:

“Aerospace systems are designed with failure in mind. This analytical approach to redundancy for critical systems — including engines — is one of the keys to aviation safety.”

A single modern turbofan installed on a typical large aircraft produces up to 115,000 pounds of thrust on takeoff. If a blade failure occurs, critical systems are routed by design to minimize the probability of a cascading loss of additional critical systems or the entire aircraft. With WCM, parts and expected loads can be constantly analyzed to see whether they should be required to be periodically replaced and/or how often they should be inspected.

4. Logistics — Global Shipping

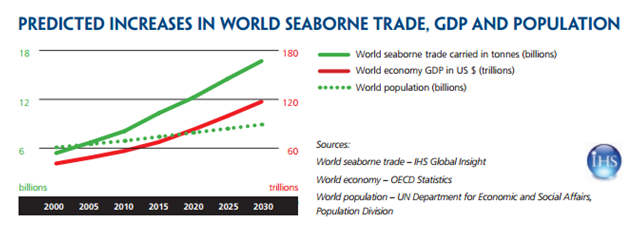

As of 2019, the total value of the annual world shipping trade had reached more than $14 trillion.

The above graph shows the predicted increases in world seaborne trade gross domestic product (GDP) and population. As you can see, by 2030 the world seaborne trade tonnage will reach a staggering 17+ billion tons of cargo.

Annually, the shipping industry transports nearly two billion tons of crude oil, one billion tons of iron ore to produce steel and 350 million tons of grain to help feed the global population. These shipments would not be possible by road, rail or air.

On a Triple E class of cargo ship — the kind operated by the biggest cargo shipping company in the world, Maersk — a typical main propulsion design features a dual 29.68-megawatt (39,800 hp), eight-cylinder, ultra-long stroke two-stroke diesel engines, driving two propellers at a design speed of 19 knots (35 km/h; 22 mph).

Just one of these ships can hold up to 18,000 TEUs (twenty-foot equivalent units), the kind of cargo containers you see stacked up on the decks of these ships.

If the recent supply-chain crisis has taught us anything, it’s that when this chain is disrupted for any reason, the costs in revenue, jobs, whole regional economies and our national security can be catastrophic.

Keeping these engines up and running is an ideal use case for WCM, especially in the harsh environment of the open ocean.

5. Facilities Management — Smart Buildings

Just like smart homes, smart buildings are becoming the way of the future.

LEED certification is a globally recognized symbol of sustainability achievement, and provides a framework for healthy, efficient, carbon and cost-savings green buildings.

Earning a LEED certification, ranging from simply certified to Platinum, is no small task. Enabling a building to become a smart building via WCM is one way to help earn that certification.

For the facilities management industry, a bevy of IoT connected smart buildings can reduce costs and boost efficiency in every aspect — from HVAC systems to elevators and other machinery needed to properly operate the building.

However, taking it a step further by intelligently integrating people management, energy savings, access control and reducing carbon footprints, the enterprises that own these buildings can generate huge ROI benefits.

According to Fortune Business Insights 2022, the smart building market came in at around $67.8 billion in 2021 and is forecasted to reach as high as $328 billion in 2029.

Power Design’s VP of Systems Technologies, Trent Morano cited the following top five trends for smart buildings:

- Net zero carbon emissions and regulatory changes

- Increasing energy consumption and costs

- Defending against cyber security threats

- Changes to workforce (e.g., hybrid work)

- Advancement in IoT and PoE solutions

The last trend is the most salient as it includes some form of facilities management. Of the five smart buildings trends listed above, WCM can certainly help with numbers one, two, and five.

Conclusion

With these top five industries valued in trillions of dollars, there are huge opportunities for wireless condition monitoring to have serious impacts on the overall optimization of operations and ROI for driving growth.

Enterprises that invest in WCM can rest assured that their place in these industries are well situated — and that is money well spent.

For a deeper dive into HID’s wireless condition monitoring solution for heavy industries such as energy production, read our case study, HID RFID Sensor TAGs Help GE Hydro.

Nick Iandolo is an experienced Senior Editor Marketing Strategist specializing in Content Marketing and Corporate Communications Writing, primarily for market-disrupting technology organizations. His work has been featured in publications such as Morning Consult, NewDesign Magazine UK, SmartCard Identity News, and Construction Outlook. Nick is also a Spartan Race athlete, and lives just outside of Boston, Mass with his wife, daughter, and Golden Retriever.