Today’s RFID Tags Reach Deep Into Many Industries

The future of RFID is here, and organizations can leverage these new technologies to provide solutions for the identification, monitoring and protection of important assets. Groundbreaking innovations are creating durable and versatile industrial RFID tags that can be combined with other technologies to create custom industrial RFID solutions and beyond. This is part of the new paradigm shift towards digital transformation in what is referred to as Industry 4.0.

HID Global’s Senior Manager of Content Marketing, Kym Elizondo-Cowley, recently sat down with three of HID’s RFID experts — Richard Aufreiter, Christian Mirus, and Claude Baucheron. They discussed how the RFID industry is evolving and addressing real-world challenges for industrial applications (like the recent GE Hydro project).

Let’s start with the basics: What is RFID technology and why is it important?

Christian Mirus: RFID stands for Radio Frequency Identification. As the name implies, we use radio frequencies to identify an object or a person. It refers to a technology whereby digital data encoded into a tag or smart label is captured by a reader via radio waves.

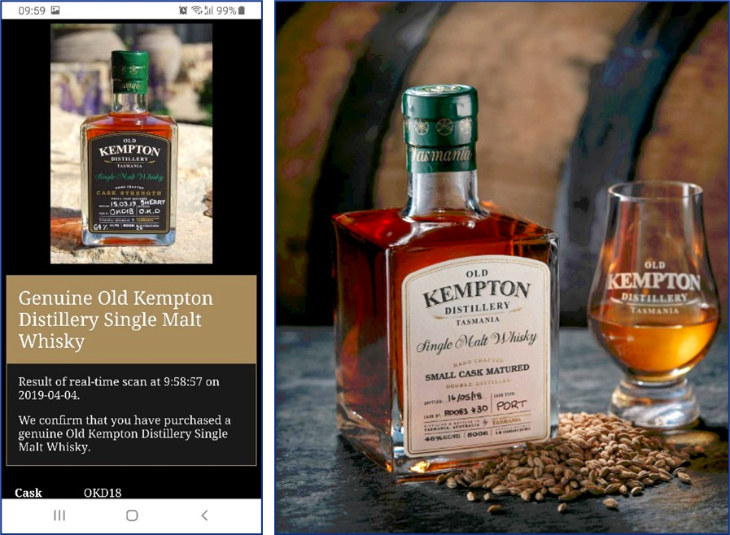

Richard Aufreiter: RFID is important because it increases efficiency, improves accuracy, saves time and resources and reduces human error. There are a few overarching reasons RFID is used. One is fast inventory and the ability to count a large number of items with the press of a button. RFID tag data can be read and written without line of sight and in bulk, so this optimizes workflows by being able to quickly count all the items on a pallet, for example, or determine what stage an item is in, such as the status of reusable kegs that need to be cleaned and refilled. Another use case is for authentication. RFID can aid anti-counterfeiting efforts or enable contactless payments. We also use RFID to monitor equipment conditions such as temperature or strain, as was the case with our GE Hydro project, for which we won an Association for Automatic Identification and Mobility [AIM] 2022 Case Study Award.

Can you tell us about the types of RFID and what they are used for?

Christian Mirus: There are really two types of RFID — active and passive. The main differences are in how they are powered, their read range, size and cost. Active RFID — which is an IoT technology — is battery-powered, and devices are typically larger due to the space needed for the battery. It provides a much longer read range (of up to 150 meters), and the internal power enables more complex capabilities like data logger or special sensors. Active solutions come at higher initial and maintenance costs because their power source needs to be periodically recharged or replaced. Active tags are often used for applications such as real-time location systems (RTLS).

Passive RFID, however, has no internal power source and can be very small. For example, some have diameters measuring only a few millimeters. Passive RFID read range is limited to a maximum of about 20 meters, but it is much less expensive and maintenance-free compared to active devices, making it ideal for larger-scale applications such as supply chain management.

Richard Aufreiter: I think it’s important to add that although these are the typical use cases, some projects utilize RFID in non-typical ways. For instance, active RFID tags can be used for condition monitoring. These are examples in which the tag needs to be intelligent. Likewise, it is also possible to use passive RFID for asset tracking or brand protection and many more applications.

What does a holistic RFID ecosystem look like?

Christian Mirus: That’s a very good question. An RFID ecosystem is comprised of a tag, a reader and software. The tags can have a multitude of different form factors and sizes to best fit the application. On the reader side you also have different possibilities like stationary readers/antennas or mobile readers which are handheld. In addition, you have the software which will collect and manage the data read from the RFID tag.

I think the question is what industry is NOT using RFID technology.

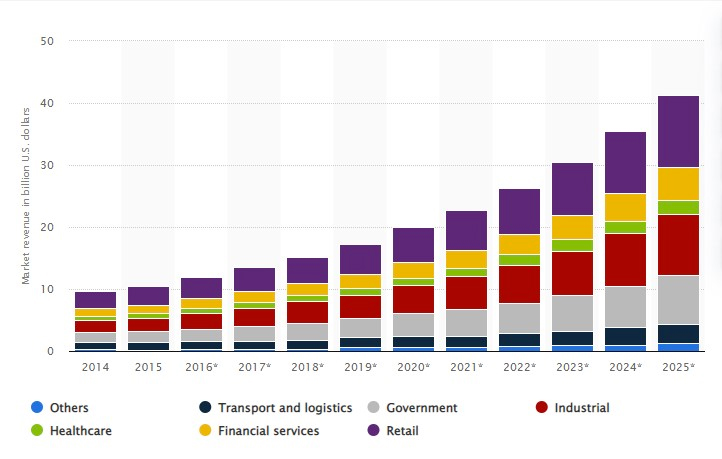

What industries are using RFID today?

Christian Mirus: I think the question is what industry is NOT using RFID technology. Because RFID has many applications, including inventory management, asset tracking, contactless payment, access control, supply chain management and even counterfeit prevention, there are use cases in every sector and vertical. This includes education, healthcare, energy and utilities, entertainment, retail, hospitality, transportation, banking and financial services, corporate enterprise and government. And that’s just to name a few that come immediately to mind.

What changes are you seeing in the RFID industry and what do you think is driving that change?

Richard Aufreiter: One of the biggest changes we are seeing in the RFID industry is standardization. Just a few years ago, every solution was a special project. As the market has matured, those early solutions created the building blocks for the standards we are seeing now, such as reader middleware. Also, tag form factors for certain uses, such as laundry or waste management are now very mature. One type of tag that many people recognize is the tag used for animal IDs. Most pet owners make sure their dog or cat is “chipped” so they can be returned if ever lost. These tags have become very standardized.

There are more and more companies understanding RFID’s benefits, and with custom designs enabling new use cases — such as the one with GE Hydro where RFID is embedded into other products — we will see more adoption. The more widespread the use becomes, the more standardizations we will see.

Christian Mirus: A major change in the RFID industry I would point to is that there are more end-users utilizing these solutions. Contactless payment is one example. Consumers no longer have to swipe a credit card or even insert it into a chip reader. Rather, debit and credit cards can simply be tapped to the reader. Consumers are also utilizing digital wallet applications for smartphones to store debit and credit cards, then the smartphone itself becomes the payment method that is tapped to the RFID reader. Today, brands are utilizing QR codes to interact with customer experience, but with a Trusted NFC RFID tag, we can add a new dimension which is the authenticity of the product verified by cryptographic means. Consumers can verify if the product is an original one with a simple tap of their smartphone, and the brands can also utilize this to enable new customer experiences. These user experiences deepen relationships with consumers and create brand loyalty.

What is the latest RFID technology advancement that excites you the most?

Richard Aufreiter: Sensors!

Christian Mirus: Sensors!

That was a quick and unanimous answer! Why are sensors such an exciting RFID advancement?

Christian Mirus: Sensors measure critical parameters and deliver needed data about objects and environments — think of applications like temperature, liquid fill level or moisture monitoring. Passive sensing devices are wireless, battery-free and require no maintenance. They are also suited for almost any environment. And they are radically lowering costs and allowing for greater data collection.

There are a lot of thrilling use cases for sensors, things like col- chain medicine monitoring and logging and logistics tracking that can facilitate large-scale health efforts like a vaccine rollout. The GE Hydro project is another great example in which passive RFID sensor tags are used to measure temperature and strain of fast-rotating parts in hydropower generators. The contactless RFID technology can work where wired sensors or infrared cannot.

Why are harsh environments an especially compelling use case for RFID?

Richard Aufreiter: It depends a bit on the use case, but there are a few reasons RFID is a good choice for a rugged application. RFID does not require line of sight; it’s robust against dirt, very chemically resistant and also heat-resistant. Even in harsh environments, RFID still has read and write capabilities. In addition, passive RFID is maintenance-free to last for many years in the application.

Tell us a little more about the GE Hydro project that HID recently won, as it relates to RFID in industrial applications. What challenge were they looking to solve and why?

Claude Baucheron: I think we can give Richard and Christian a little break on answers and I will take this one!

Yes, it's a very interesting question. GE Hydro is a subsidiary of GE Renewable Energy. They have hydropower turbine installations all over the world, including federal utilities and independent power producers. The efficient and continual operation of the hydropower turbines is extremely important to GE Hydro as these customer installations are responsible for powering the electrical grid for entire cities in some cases.

GE Hydro was looking for a solution to measure temperature and strain in a particularly harsh environment. The turbines spin a generator to create electricity. The amount of energy created depends on how much water passes through the system. So, you can imagine, there are a lot of metal parts moving at enormous speeds and high temperatures. The turbines’ metal parts spin extremely fast, at about 800 rpm which is the equivalent of about 250 kph. Inside the enclosure it’s wet with high currents, resulting in electromagnetic fields. If the turbine and generator are too strained and get too hot, the system can fail. Monitoring the environment in the turbines and the ability to predict or prevent equipment breakdown are critical.

The project started in 2019. We were already working with Asygn to develop a chip with integrated passive sensor technology when GE Hydro reached out with this use case and the timing couldn’t have been better. We met and decided to work together on the project.

We collaborated with Asygn and developed a UHF RFID tag that contains an antenna with an embedded passive sensor that would affix to the metal as a sticker. Very easy, right? The tags measure temperature and strain and communicate this data to the reader at predetermined intervals. You don't need to have cables everywhere because only the reader requires electricity. It’s a very economical way to monitor the equipment.

We started testing them on GE’s hydropower turbines in France. At each electrical dam you have somewhere between 5-10 turbines and each turbine needed 20-40 tags. Data on the turbine temperature and strain were collected over a number of months, optimizing the yield of the systems. The trial extended to Canada as well as China, which is one of the largest hydropower plant users in the world.

What other RFID use cases for condition monitoring is this new rugged RFID TAG illuminating?

Christian Mirus: So, we are now extending this new tag to not only measure temperature but also measure constraint, which is opening a lot of new applications. For example, the new tag can monitor the electric cables that power trains for load and atmospheric conditions. This has never been done before. And because we’ve just developed this technology, there are more use cases that are coming to light.

Richard Aufreiter: What is of importance with sensor technology is that customers work with a vendor that is, in general, chip agnostic. There are options depending on the need, whether that is precise temperature measurement, high-speed readings or various physical parameters like strain or humidity, which imply different price points. These specialized requirements mean you want to make sure that you get the right chip and form factor for your unique use case.

For a deeper dive into how HID Global’s custom RFID solutions can help your industrial enterprise working in harsh environments, download a copy of the GE Hydro case study.

*Source: Statista.com

Nick Iandolo is an experienced Senior Marketing Strategist specializing in Content Marketing and Corporate Communications Writing, primarily for market-disrupting technology organizations. He has a knack for taking highly technical materials from subject matter experts and translating them into actionable marketing collateral for both digital and print. His most recent roles were senior content creator positions for Exponent and PTC, where his work has been featured in publications such as Morning Consult, NewDesign Magazine UK, SmartCard Identity News, and Construction Outlook. In his personal life, he is a creative writer penning digital tech trends blogs and science fiction stories, and he is also an enthusiast Spartan Race athlete. Nick lives just outside of Boston Mass with his wife, daughter and Golden Retriever.